A yakazara butterfly valveinoratidza chimiro chakazara mukati memuviri wevharuvhu. Iyi dhizaini yakanyatso gadzirwa kune corrosion-resistant application.

"Yakanyatsogadziriswa" zvinoreva kuti kwete chete diski yakavharwa zvachose, asiwo chigaro chakavharwa zvachose, kuve nechokwadi chekuzviparadzanisa kwakakwana pakati penhau nesimbi.

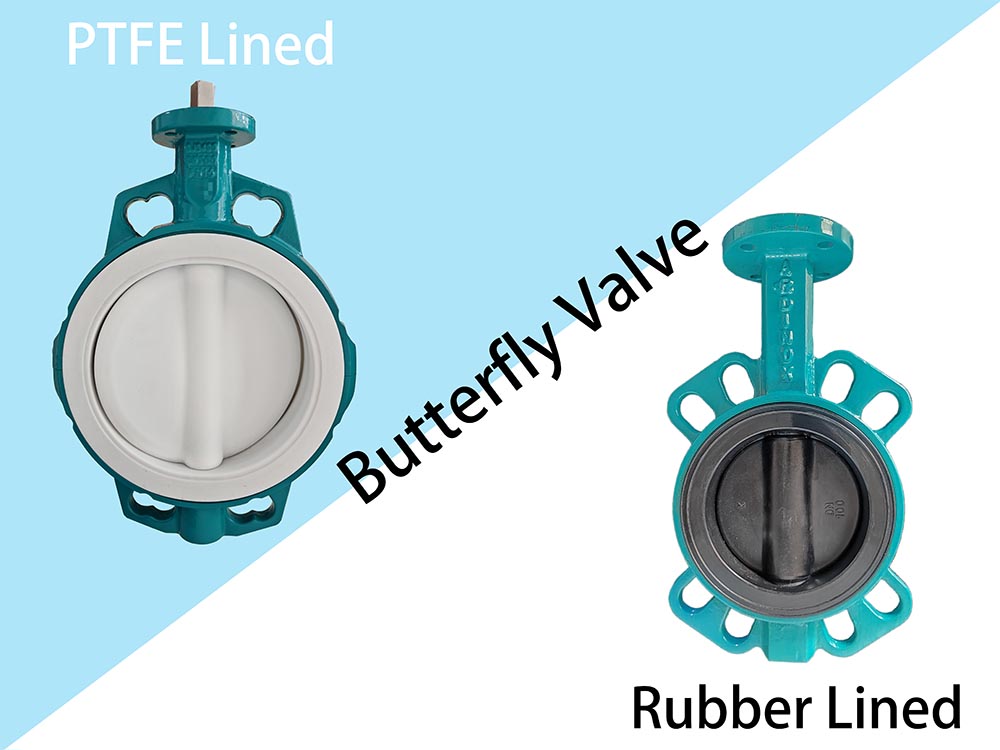

1. Zvinhu zviviri zvakajairika zvekugadzira

a. PTFE (polytetrafluoroethylene, perfluoroplastic) inonamira butterfly valve

b. Rubber lining butterfly valve

| Rudzi rwezvinhu: | Polytetrafluoroethylene (PTFE) mutsara | Rubber lining (semuenzaniso, EPDM, Viton, NBR) |

| Lining Process | Yakanyungudutswa PTFE/PFA inodururwa mune dovetail groove pamuviri/disc, kuwana isina musono chisungo. | Iyo inobva yanyudzwa zvakananga (kupisa-yakarapwa) pasimbi, ichiita chisimbiso chakasimba, chakakosha. |

| Core Features | - Yakanakisa corrosion kuramba (inopokana kune angangoita ese maasidhi, mabhesi, uye organic solvents) - Yakakwira tembiricha kuramba (inoramba ichishanda tembiricha inosvika 180°C) - Yakaderera friction coefficient uye isina-stick zvivakwa, yakakodzera kune yakakwirira-kuchena midhiya

| - Yakanakisa elasticity uye yakanakisa yekuisa chisimbiso kuita (zviri nyore kuwana zero kuvuza) - Mutengo wakaderera uye wakanaka kupfeka kuramba kune isiri-corrosive media - Yakadzika tembiricha kuramba (kazhinji -20°C kusvika ku180°C, zvichienderana nerudzi rwerabha)

|

| Inoshanda Media | Asidhi yakasimba (senge sulfuric acid uye hydrochloric acid), mabhesi akasimba, organic solvents, yakanyanya kuchena zvinwiwa. | mvura, tsvina, asidhi isina simba uye mabhesi, slurries, uye chikafu-giredhi media |

| Typical Applications | Chemical Indasitiri (asidhi uye alkali kufambisa), Pharmaceutical Indasitiri (yakakwirira-kuchena zvinhu kutamiswa) | Kugadziriswa kweMvura (kugadziriswa kwemvura yetsvina, pombi yemvura), HVAC Systems, Chikafu uye Chinwiwa Indasitiri, Migodhi (slurry transfer) |

2. Detailed Process Matanho nokuda PTFE-lined Valve Discs

2.1 Metal Disc Kugadzirira

a.. Kanda kana muchina simbi disc core, kuve nechokwadi chekuti nzvimbo yacho yakachena uye haina mafuta uye kusvibiswa.

.

2.2 PTFE Powder Molding uye Preforming

a. Isa yakanyatsoverengerwa huwandu hwePTFE hupfu (kana premix) muforoma, isa simbi butterfly valve core, wobva wawedzera PTFE poda.

b. Zvishoma nezvishoma isa vacuum (exhaust) uye kumanikidza (kudzvanya kana isostatic kudzvanya) kuumba green embryo. Isostatic molding: Nyura mold mumvura uye shandisa yunifomu kumanikidza kumativi ose (mvura pressure conduction) kuti ive nechokwadi cheunifomu uye dense chimiro (porosity yakaderera se <1%).

2.3 Kuchema uye Kurapa

a. Isai embryo yakasvibirira muchoto uye sinter pa 380 ° C kwemaawa 5-24 (zvishoma nezvishoma kuwedzera kutonhora kuti urege kuputika).

b. Zvishoma nezvishoma kutonhora kusvika kune tembiricha yekamuri kubvumira PTFE kuti ijekese uye fuse nesimbi yesimbi, ichigadzira isina musono coating (ukobvu hunodzorwa kuve 3-10mm, inogadziriswa zvinoenderana nemamiriro evacuum).

2.4 Kugadzira uye Kupedzisa:

Shandisa lathe kana CNC muchina kuchina madhayamita emukati nekunze kuti dhisiki uye chigaro chikwane zvakakwana (kushivirira kwakasimba, semuenzaniso, ± 0.01mm).

2.5 Kuongorora uye Kuongororwa Kwemhando:

a. Ukobvu kuyerwa: Ita shuwa diki lining ye3mm, kana seyakagadzirirwa.

b. Spark Muedzo: 35,000 volts yekuomesa bvunzo (hapana kuparara kunoratidza kugamuchirwa).

c. Vacuum/Simba Muedzo: Inoteedzera mamiriro ekushanda kuti atarise kuvuza uye permeability (maererano neEN 12266-1 kana API 598).

d. Conductivity Test (inosarudza): Surface kuramba <10⁶Ω yekushandiswa kwekudzivirira-kuputika.

3. Detailed Process Steps for EPDM-lined Discs

3.1 Metal Disc Kugadzirira

a. Kanda kana muchina musimboti wesimbi kuitira kuti pave pakachena, pasina ngura.

b. Jecha kana makemikari etch pamusoro (roughness Ra 3-6μm) kukurudzira EPDM adhesion.

3.2 EPDM Musanganiswa Kushandisa uye Kugadzirisa

EPDM isina kuvharwa (shiti kana mvura) inoiswa muforoma, ichiputira mukati mesimbi yesimbi. Uchishandisa compression molding kana kudurura, zvakaenzana kugovera koniyumu pamusoro pevhavha disc pamusoro kuti uite muviri wakasvibira. Chengetedza kukora kwe2-5 mm, kuve nechokwadi chekuvhara kumativi ose e disc.

3.3 Kurapa

Muviri wakasvibira unoiswa mu autoclave uye unopisa nemhepo kana mhepo inopisa (150-180 ° C, kumanikidza> 700 psi, kwemaawa 1-4).

Iyo nzira yekurapa inoyambuka-inosanganisa uye inorapa iyo EPDM, kemikari uye nemuchina ichiisunga kusimbi yesimbi kuti iite isina musono, imwe-chidimbu lining. Wedzera tembiricha zvishoma nezvishoma kudzivirira mabhuru emhepo kana kutsemuka.

3.4 Machining Kupedza

Mushure mekutonhodza, cheka mukati nekunze kwemukati uchishandisa CNC lathe kuona kuti dhisiki nechigaro zvinokwana zvakakwana (kushivirira ± 0.05 mm). Bvisa rabha rakawandisa uye ongorora iyo yekumucheto mbiri (Ni-Cu coating inosarudzika yekuvandudza kupfeka kuramba).

3.5 Kuongorora Kwemhando uye Kuedzwa

a. Ukobvu uye Adhesion Testing: Ultrasonic ukobvu kuyerwa (zvishoma 2mm); Tensile Testing (peel simba> 10 N/cm).

b. Performance Verification: Bubble Tight Seal Test (API 598 standard); Pressure / Vacuum Test (PN10-16, kusagadzikana kumanikidza kuramba).

c. Kemikari / Kuchembera Muedzo: Kunyudzwa muasidhi uye alkaline midhiya, kutarisa kuwedzera <5%; Kuchembera kwepamusoro-soro (120°C, 72h).

4. Nhungamiro Yekusarudza

PTFE linings dzakakodzera kune zvakanyanya corrosive media (senge acids, alkalis, uye zvinonyungudutsa), nepo EPDM linings dzakakodzera mvura-based, mild media (senge mvura uye dilute acids). Rongedza kuenderana kwemakemikari, tembiricha, kudzvanywa, uye mutengo kukwirisa application. Zhongfa Valve inogadzira mavharuvhu akazara ane mitsetse ine wafer, flange, uye mabhegi sarudzo. Ndapota taura nesu nemibvunzo ipi zvayo.

Nguva yekutumira: Oct-28-2025